First you need to have the proper equipment. Or else bad things will happen.

The advantages of using an Arc Welder is you do not have to worry about your wire getting tangled up. Also you do not have to clean out the tip of the machine. Some disadvantages is you have to chip the slag and the weld does not come out as nice. Make sure the amperage matches the thickness of metal you are welding on. If you need any help see chart below:

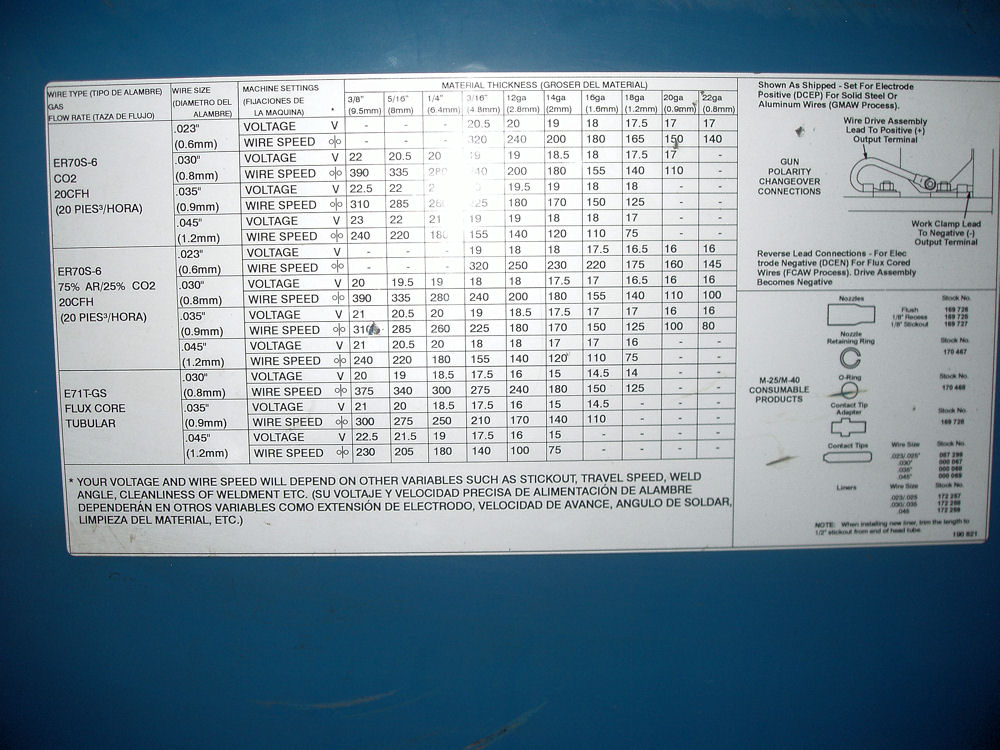

The advantages and disadvantages are the same in arc welder except you switch the data. Make sure the wire speed and the amount of Inert gas you use match. If you need help see chart below:

In order here is a how you turn on the machine,use it,turn it off properly.

First you need to practice striking your ark. Then you weld away from you. As you weld you do not want your electrode to get to close to the metal where it will stick or too far away where it won't burn. Always remember to lean on a table or working area for steadiness. Do not weld too fast to where the pieces are not welded together properly. Or go too slow whereyou are piling up uneeded metal.

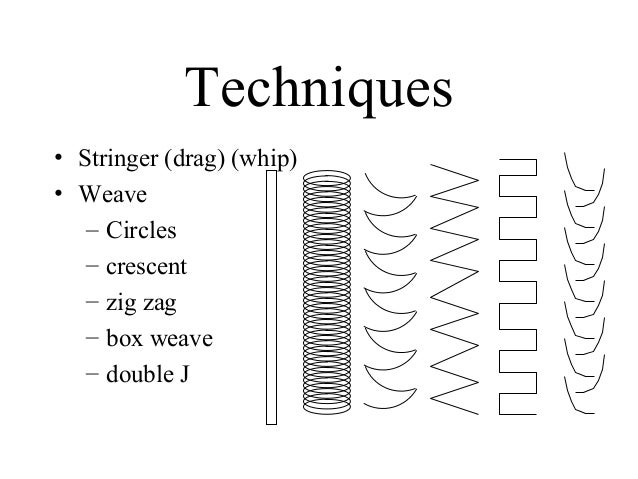

Vertical is tricky because of the gravity making your metal runny. So all you really got to do is strike your ark. Then weld just like the horizontal. Except welding up. The trick is to get your rod close to the metal without letting it stick. Then you weld extremely tiny circles so that you are pushing your slag up the metal so it is not running off.

Check to make sure you have a wire speed that matches the electric and the thickness of the metal. Just follow the same steps as arc welder. Except you do not have to strike an arc. When you are done either break off or cut the excess wire.

You can weld in a triangle shape or an upside down carrot.